Page 38 - PlanWorld_2018EN

P. 38

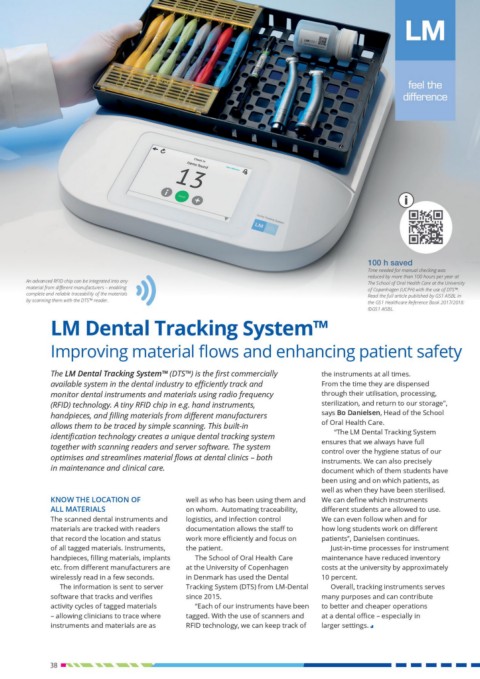

An advanced RFID chip can be integrated into any 100 h saved

material from different manufacturers – enabling

complete and reliable traceability of the materials Time needed for manual checking was

by scanning them with the DTS™ reader. reduced by more than 100 hours per year at

The School of Oral Health Care at the University

of Copenhagen (UCPH) with the use of DTS™.

Read the full article published by GS1 AISBL in

the GS1 Healthcare Reference Book 2017/2018:

©GS1 AISBL.

LM Dental Tracking System™

Improving material flows and enhancing patient safety

The LM Dental Tracking System™ (DTS™) is the first commercially the instruments at all times.

available system in the dental industry to efficiently track and From the time they are dispensed

monitor dental instruments and materials using radio frequency through their utilisation, processing,

(RFID) technology. A tiny RFID chip in e.g. hand instruments, sterilization, and return to our storage",

handpieces, and filling materials from different manufacturers says Bo Danielsen, Head of the School

allows them to be traced by simple scanning. This built-in of Oral Health Care.

identification technology creates a unique dental tracking system

together with scanning readers and server software. The system “The LM Dental Tracking System

optimises and streamlines material flows at dental clinics – both ensures that we always have full

in maintenance and clinical care. control over the hygiene status of our

instruments. We can also precisely

KNOW THE LOCATION OF well as who has been using them and document which of them students have

ALL MATERIALS on whom. Automating traceability, been using and on which patients, as

The scanned dental instruments and logistics, and infection control well as when they have been sterilised.

materials are tracked with readers documentation allows the staff to We can define which instruments

that record the location and status work more efficiently and focus on different students are allowed to use.

of all tagged materials. Instruments, the patient. We can even follow when and for

handpieces, filling materials, implants how long students work on different

etc. from different manufacturers are The School of Oral Health Care patients”, Danielsen continues.

wirelessly read in a few seconds. at the University of Copenhagen

in Denmark has used the Dental Just-in-time processes for instrument

The information is sent to server Tracking System (DTS) from LM-Dental maintenance have reduced inventory

software that tracks and verifies since 2015. costs at the university by approximately

activity cycles of tagged materials 10 percent.

– allowing clinicians to trace where “Each of our instruments have been

instruments and materials are as tagged. With the use of scanners and Overall, tracking instruments serves

RFID technology, we can keep track of many purposes and can contribute

to better and cheaper operations

at a dental office – especially in

larger settings. ▟

38