Page 20 - PlanWorld_2021

P. 20

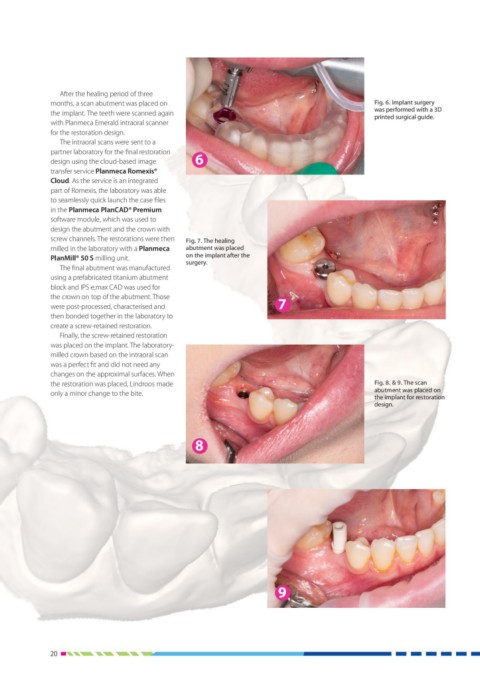

After the healing period of three 6 Fig. 6. Implant surgery

months, a scan abutment was placed on was performed with a 3D

the implant. The teeth were scanned again Fig. 7. The healing printed surgical guide.

with Planmeca Emerald intraoral scanner abutment was placed Fig. 8. & 9. The scan

for the restoration design. on the implant after the abutment was placed on

surgery. the implant for restoration

The intraoral scans were sent to a design.

partner laboratory for the final restoration 7

design using the cloud-based image

transfer service Planmeca Romexis®

Cloud. As the service is an integrated

part of Romexis, the laboratory was able

to seamlessly quick launch the case files

in the Planmeca PlanCAD® Premium

software module, which was used to

design the abutment and the crown with

screw channels. The restorations were then

milled in the laboratory with a Planmeca

PlanMill® 50 S milling unit.

The final abutment was manufactured

using a prefabricated titanium abutment

block and IPS e.max CAD was used for

the crown on top of the abutment. Those

were post-processed, characterised and

then bonded together in the laboratory to

create a screw-retained restoration.

Finally, the screw-retained restoration

was placed on the implant. The laboratory-

milled crown based on the intraoral scan

was a perfect fit and did not need any

changes on the approximal surfaces. When

the restoration was placed, Lindroos made

only a minor change to the bite.

8

9

20